SPXU series scraper kub exchanger

SPXU series scraper heat exchanger unit yog ib hom tshiab ntawm scraper heat exchanger, tuaj yeem siv los ua kom sov thiab txias ntau yam khoom viscosity, tshwj xeeb tshaj yog rau cov khoom tuab thiab tuab, nrog rau cov khoom zoo, kev noj qab haus huv, kev ua haujlwm kub hloov pauv, pheej yig nta. .

• Compact qauv tsim

• Robust spindle txuas (60mm) kev tsim kho

• Durable scraper zoo thiab tshuab

• High precision machining technology

• Cov khoom siv hluav taws xob hloov hluav taws xob lub tog raj kheej thiab kev ua haujlwm sab hauv

• Lub tog raj kheej hloov cua sov tuaj yeem raug tshem tawm thiab hloov nyias

• Sib koom siv lub cev muaj zog tsav - tsis muaj kev sib txuas, siv hlua lossis rub

• Concentric lossis eccentric ncej mounting

• Ua raws li GMP, CFIA, 3A thiab ASME tus qauv tsim, FDA xaiv tau

Cov khoom ua tiav los ntawm SSHEs.

Lub tshuab hluav taws xob hluav taws xob hluav taws xob tuaj yeem siv tau nyob rau hauv yuav luag txhua txoj haujlwm txuas ntxiv rau kev siv cov kua dej los yog cov kua dej khov, thiab tuaj yeem muaj cov ntawv thov hauv qab no:

Daim ntawv thov kev lag luam

Cua sov

Aseptic txias

Cryogenic cua txias

Crystallization

Tshuaj tua kab mob.

Pasteurization

Jelling

Khoom specification

Qhov chaw rau SPXU scraper heat exchangers tuaj yeem tsim nyob rau hauv ntau yam kev teeb tsa thiab cov ntaub ntawv, yog li txhua chav hloov hluav taws xob tuaj yeem ua tus kheej kom tau raws li cov txheej txheem tshwj xeeb ntawm txhua daim ntawv thov. Cov khoom ua raws li GMP, CFIA, 3A thiab ASME tus qauv tsim thiab tuaj yeem muab nrog FDA ntawv pov thawj.

• Tsav lub cev muaj zog ntawm 5.5 mus rau 22kW

• Ntau yam ntawm cov zis ceev (100 ~ 350 r / min)

• Chromium-nickel-plated carbon steel thiab 316 stainless hlau tshav kub hloov raj tsim los txhim kho cua sov hloov

• Txheem stainless hlau los yog yas scraper, kev cai yas scraper uas tuaj yeem ntes hlau

• Spindle diameters raws li cov yam ntxwv ntawm cov kua dej (120, 130 thiab 140mm)

• Ib leeg lossis ob lub tshuab foob yog xaiv tau

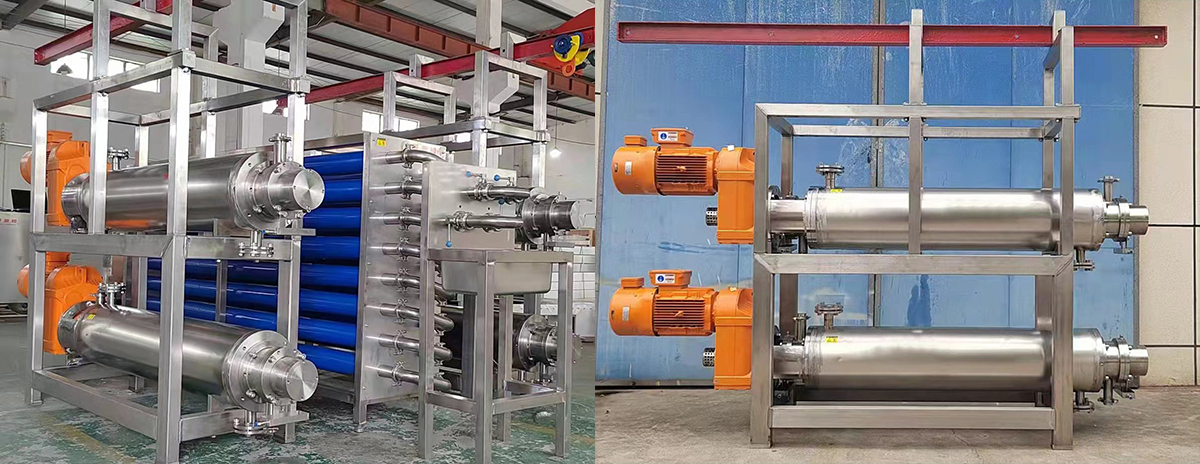

Cov duab ntawm SSHEs

Dielectric interlayer

Dielectric interlayers ntawm scraper kub exchangers rau kua, chav los yog ncaj qha expansion tub yees

Jacket Siab ntawm dielectric sandwich

232 psi (16 MPa) @ 400 ° F (204 ° C) lossis 116 psi (0.8MPa) @ 400 ° F (204 ° C)

Khoom Sab Siab. Khoom sab siab

435 psi (3MPa) @ 400 ° F (204 ° C) lossis 870 psi (6MPa) @ 400 ° F (204 ° C)

Thaum tshav kub kub hloov lub tog raj kheej

• Thermal conductivity thiab phab ntsa thickness yog qhov tseem ceeb tsim kev txiav txim siab hauv kev xaiv cov cua kub hloov cov raj. Lub tog raj kheej phab ntsa thickness yog precisely tsim los txo cov tshav kub hloov tsis kam thaum maximizing cov qauv stability.

• Ntshiab npib tsib xee lub tog raj kheej nrog siab thermal conductivity. Sab hauv ntawm lub tog raj kheej yog plated nrog nyuaj chrome thiab tom qab ntawd hauv av thiab polished kom nws du kom tiv thaiv kev puas tsuaj los ntawm scrapers thiab cov khoom sib tsoo.

• Chromium-plated carbon steel tubes muab siab thermal conductivity ntawm tus nqi tsim nyog rau cov khoom xws li txiv laum huab xeeb, luv luv thiab margarine.

• Stainless hlau raj tshwj xeeb tsim los txhim kho cov cua sov hloov rau cov khoom siv acidic thiab muab kev yooj yim ntawm kev siv tshuaj ntxuav.

siv zog

Scrapers yog teem rau hauv staggered kab ntawm lub ncej. Lub scraper yog ruaj ntseg rau lub ncej ntawm lub scraper cua sov exchanger los ntawm ib tug robust, ruaj, tshwj xeeb tshaj yog tsim "universal tus pin". Cov pins no tuaj yeem raug tshem tawm sai thiab yooj yim thiab cov scraper hloov.

foob

Mechanical seals yog tshwj xeeb uas tsim los kom yooj yim rau kev sib sau thiab tswj, thiab kom ntseeg tau tias kev ua haujlwm ruaj khov.

Cov cua kub ntawm cov khoom thiab lub sij hawm nyob rau hauv lub tshav kub exchanger yog tswj los ntawm lub ntim ntawm cov khoom. Thaum tshav kub kub exchangers nrog me me txoj kab uas hla shafts muab loj annular khoob thiab ncua sij hawm nyob rau hauv lub sij hawm, thiab muaj peev xwm lis tej khoom thiab cov khoom uas loj hais. Thaum tshav kub kub exchangers nrog loj txoj kab uas hla shafts muab me me annular khoob rau high speeds thiab turbulence, thiab muaj ntau dua tshav kub hloov thiab cov khoom nyob rau lub sij hawm luv dua.

Tsav lub cev muaj zog

Xaiv txoj cai tsav lub cev muaj zog rau scraper heat exchanger muab qhov kev ua tau zoo tshaj plaws nyob rau hauv txhua daim ntawv thov, kom ntseeg tau tias cov khoom siv tau sib zog nqus thiab tsis tu ncua scraped tawm ntawm phab ntsa hloov hluav taws xob. Lub tshuab hluav taws xob hluav taws xob hluav taws xob tau nruab nrog lub tshuab hluav taws xob ncaj qha nrog ntau lub zog xaiv los muab kev ua haujlwm zoo rau cov ntawv thov tshwj xeeb.

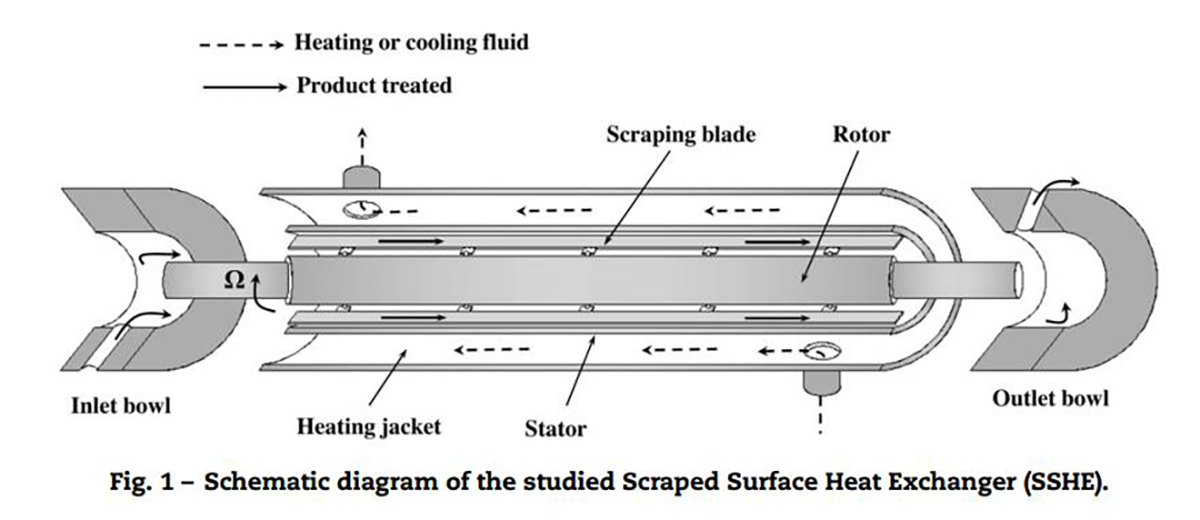

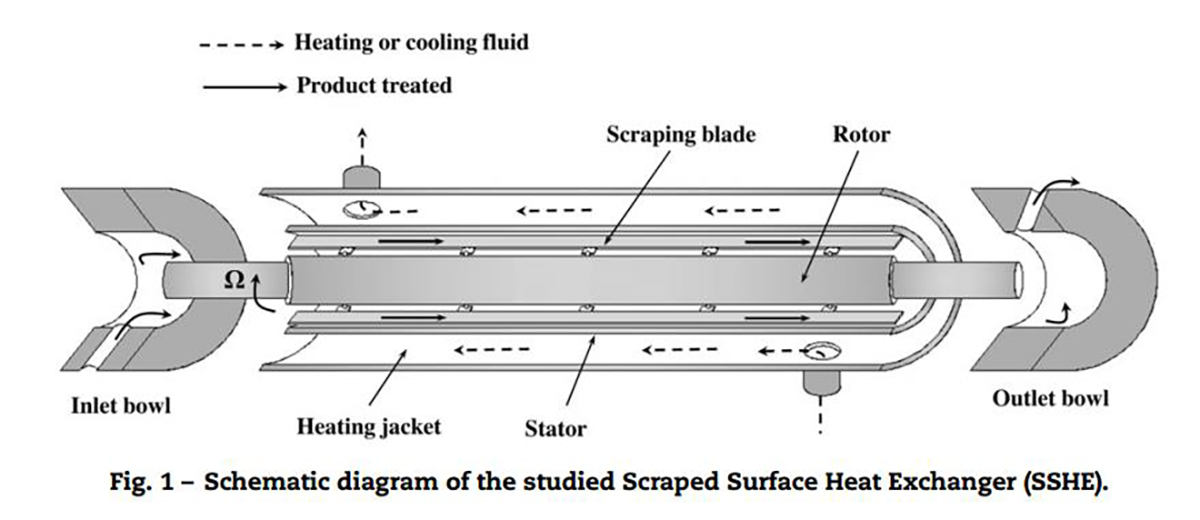

Sab hauv qauv ntawm SSHEs

Thaum tshav kub kub-sensitive khoom

Cov khoom degraded los ntawm lub sij hawm raug tshav kub tuaj yeem kho tau zoo hauv scraper heat exchangers. Lub scraper tiv thaiv cov khoom los ntawm qhov seem ntawm lub tshav kub hloov chaw los ntawm kev tshem tawm tas li thiab rov ua dua cov yeeb yaj kiab. Vim tias tsuas yog ib qho me me ntawm cov khoom raug cuam tshuam rau qhov chaw overheated rau lub sijhawm luv luv, kev kub hnyiab tuaj yeem txo qis lossis tshem tawm kom tsis txhob coking.

Cov khoom nplaum

Scraper heat exchangers tuav cov khoom nplaum zoo dua li cov phaj los yog lub raj cua kub exchangers. Cov khoom siv zaj duab xis yog tsis tu ncua scraped tawm ntawm lub tshav kub hloov mus rau phab ntsa kom tsim tau cov cua kub hloov siab heev. Kev ntxhov siab tsis tu ncua yuav ua rau muaj kev kub ntxhov, ua rau cua sov lossis cua txias ntau dua; Lub siab poob tuaj yeem tswj tau zoo los ntawm cov khoom lag luam annulus cheeb tsam; Kev ntxhov siab tuaj yeem tshem tawm qhov chaw nyob ruaj khov thiab khaws cov khoom lag luam; Thiab nws yooj yim dua los ntxuav.

Granular khoom

Hauv scraper heat exchangers, nws yog ib qho yooj yim los lis cov khoom nrog cov khoom uas zoo li clog cov pa hluav taws kub exchangers, ib qho teeb meem uas yog zam nyob rau hauv scraper heat exchangers.

Crystalline khoom

Cov khoom siv crystallized yog qhov zoo tagnrho rau kev ua cov khoom siv hluav taws xob kub exchangers. Cov khoom siv crystallizes ntawm phab ntsa hloov hluav taws xob, thiab cov scraper tshem tawm nws thiab ua kom lub ntsej muag huv. Qhov zoo tshaj plaws supercooling degree thiab muaj zog agitation tuaj yeem tsim ib qho zoo crystal nucleus.

Kev ua tshuaj lom neeg

Kev lag luam tshuaj, tshuaj thiab petrochemical tuaj yeem siv cov khoom siv hluav taws xob sib hloov hauv ntau cov txheej txheem, uas tuaj yeem muab faib ua plaub pawg.

1. Cua sov thiab txias: Rau scraper heat exchangers, tuav cov ntaub ntawv nplaum heev tsis yog ib qho teeb meem. Khawb cov khoom ua yeeb yaj kiab los ntawm qhov chaw ntawm cov yeeb nkab cua sov lossis cov yeeb nkab txias ob peb zaug hauv ib feeb kom tiv thaiv kev tsim cov nplai lossis cov txheej khov kom tiv thaiv kom tsis txhob muaj cua sov ntxiv. Tag nrho cov khoom ntws cheeb tsam yog qhov loj, yog li lub siab poob qis tsawg.

2. Crystallization: Cov khoom siv hluav taws xob hluav taws xob tuaj yeem siv los ua qhov sib txawv kom txias cov khoom mus rau qhov kub thiab txias, thaum lub sijhawm cov kua nplaum pib crystallize. Circulating los ntawm lub tshav kub exchanger ntawm ib tug siab txaus tus nqi tsim crystal nuclei, uas loj hlob mus rau cais tom qab ncav cuag ib tug zaum kawg kub. Ciab thiab lwm yam khoom siv kho kom zoo tuaj yeem ua kom txias mus rau qhov chaw melting hauv ib qho kev ua haujlwm, tom qab ntawd muab ntim rau hauv pwm, muab tso rau hauv ib qho chaw txias los yog granulated siv lwm yam khoom siv.

3. Kev tswj cov tshuaj tiv thaiv: scraper heat exchangers tuaj yeem siv los tsav cov tshuaj lom neeg los ntawm kev tswj cov khoom cua sov. Rau exothermic cov tshuaj tiv thaiv, cov khoom siv hluav taws xob tuaj yeem tshem tawm cov tshuaj tiv thaiv tshav kub kom tiv thaiv cov khoom degradation los yog kev phiv tshwm sim. Lub tshav kub exchanger tuaj yeem ua haujlwm ntawm qhov siab heev ntawm 870 psi (6MPa).

4. Whipped / Inflated khoom:

Cov khoom siv hluav taws xob hluav taws xob xa hluav taws xob xa tawm cov txiaj ntsig zoo sib xyaw rau cov khoom lag luam thaum nws ntws raws cov rotating axis, yog li cov roj tuaj yeem sib xyaw rau hauv cov khoom thaum cua sov lossis txias nws. Cov khoom lag luam tuaj yeem ua tau los ntawm kev ntxiv roj es tsis yog kev cia siab rau cov tshuaj tiv thaiv los ua npuas ua cov khoom lag luam.

Cov khoom ua tiav

Kev thov ntawm scraper kub exchanger

Cov khoom siv viscosity siab

Surimi, lws suav sauce, custard Sauce, chocolate sauce, whipped / aerated khoom, txiv laum huab xeeb, mashed qos yaj ywm, starch paste, qhaub cij sauce, gelatin, Mechanical boneless minced nqaij, me nyuam mos zaub mov, nougat, daim tawv nqaij cream, tshuaj zawv plaub hau, thiab lwm yam.

Thaum tshav kub kub rhiab khoom

Qe kua khoom, gravy, txiv hmab txiv ntoo npaj, cream cheese, whey, soy sauce, protein kua, tws ntses, thiab lwm yamCrystallization thiab theem transformationSugar concentrate, margarine, shortening, lard, fudge, solvents, fatty acids, roj av jelly, npias thiab caw, thiab lwm yam

Granular khoom

Cov nqaij minced, nqaij qaib nuggets, ntses noj, zaub mov tsiaj, preserves, txiv hmab txiv ntoo yogurt, txiv hmab txiv ntoo cov khoom xyaw, ncuav qab zib filling, smoothies, pudding, zaub slices, Lao Gan Ma, thiab lwm yam Viscous materialCaramel, cheese sauce, lecithin, cheese, khoom qab zib, poov xab extract, mascara , tshuaj txhuam hniav, siv quav ciab, thiab lwm yam