Margarine Production Process

Margarine Production Process

Margarine ntau lawm suav nrog ob ntu: kev npaj cov khoom siv raw thiab txias thiab plasticizing. Cov cuab yeej tseem ceeb suav nrog kev npaj tso tsheb hlau luam, HP twj tso kua mis, tus neeg pov npav (scraped nto tshav kub exchanger), pin rotor tshuab, tub yees chav tsev, margarine filling tshuab thiab lwm yam.

Cov txheej txheem qub yog qhov sib xyaw ntawm cov roj theem thiab theem dej, qhov ntsuas thiab qhov sib xyaw emulsification ntawm cov roj theem thiab cov dej theem, thiaj li npaj cov khoom noj rau cov txheej txheem tom ntej. Cov txheej txheem kawg yog tas li txias plasticizing thiab ntim khoom.

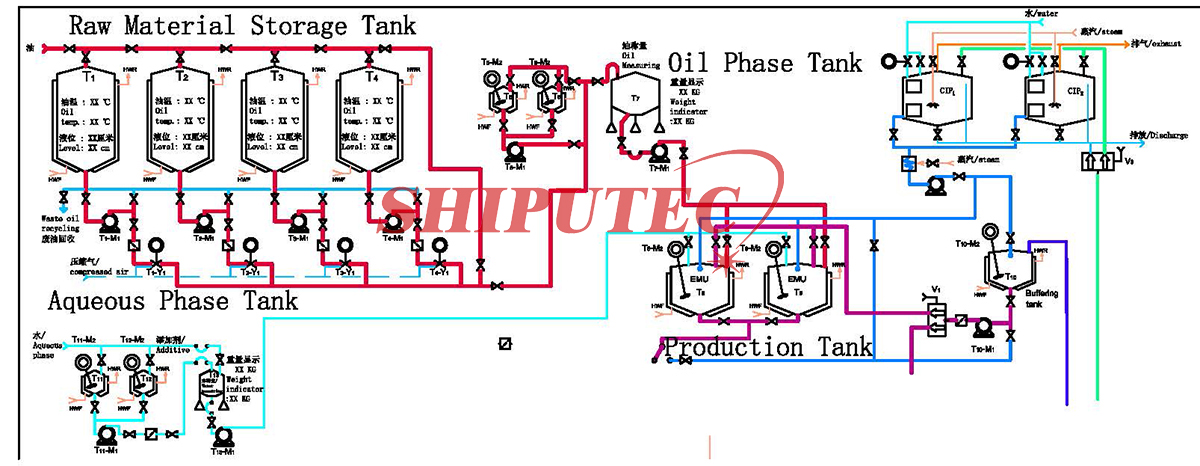

Cov txheej txheem npaj raw khoom ntawm margarine yog qhia hauv daim duab 1:

- 1.Cov mis nyuj fermented

Qee cov mis margarine ntxiv cov mis nyuj, thiab cov mis nyuj tom qab cov kab mob lactic acid fermentation tuaj yeem tsim cov khoom qab zib zoo sib xws, yog li lub Hoobkas rau fermented mis nyuj thiab dej sib xyaw.

- 2.Kev sib tov dej

Cov dej thiab dej-soluble additives nyob rau hauv cov mis ntawm margarine, xws li fermented mis nyuj, ntsev, preservatives, thiab lwm yam, yog ntxiv rau cov dej theem sib tov thiab lub metering tank nyob rau hauv cov kev faib ua feem rau do thiab mix, thiaj li hais tias cov dej theem. Cheebtsam yog yaj mus rau hauv ib qho kev daws teeb meem.

- 3.Roj theem sib tov

Cov roj nyoos ntawm cov khoom sib txawv yog thawj zaug sib xyaw rau hauv cov roj sib xyaw ua ke raws li kev faib ua feem, thiab tom qab ntawd cov roj-soluble additives, xws li emulsifier, antioxidant, roj-soluble pigment, roj-soluble cellulose, thiab lwm yam, ntxiv rau. cov roj theem raws li qhov kev faib ua feem, sib tov nrog lub metering tank, thiab stirred los tsim ib tug uniform roj theem.

- 4.Cov emulsion

Lub hom phiaj emulsification ntawm margarine yog ua kom lub aqueous theem tusyees thiab stably dispersed nyob rau hauv cov roj theem, thiab lub dispersion degree ntawm aqueous theem muaj ib tug zoo heev cuam tshuam rau qhov zoo ntawm cov khoom. Vim hais tias qhov tsw ntawm margarine yog ze ze rau qhov loj ntawm cov dej theem hais, kev nthuav tawm ntawm cov kab mob yog nqa tawm hauv cov dej theem, qhov loj ntawm cov kab mob dav dav yog 1-5 microns, yog li cov dej hauv 10-20. microns los yog ntau yam me me tuaj yeem txwv qhov kev nthuav tawm ntawm cov kab mob, yog li cov dej theem dispersion zoo heev, cov dej theem me me dhau lawm yuav ua rau cov margarine poob qab; Dispersing tsis txaus, dej theem particle loj dhau lawm, yuav ua rau margarine corrupt metamorphism. Kev sib raug zoo ntawm cov degree ntawm aqueous theem dispersion nyob rau hauv margarine thiab qhov xwm ntawm cov khoom yog roughly raws li nram no:

| 水滴直径 Water drop dimension (Lub micrometer) | Saj ntawm Margarine |

| tsawg dua 1 (li 80-85% ntawm cov dej theem) | Hnyav thiab tsawg saj |

| 30-40 (tsawg dua 1% ntawm cov dej theem) | Zoo saj, yooj yim rau putrid |

| 1-5 (li 95% ntawm cov dej theem) | Zoo saj, tsis yooj yim rau putrid |

| 5-10 (li 4% ntawm cov dej theem) | |

| 10-20 (kwv yees li 1% ntawm cov dej theem) |

Nws tuaj yeem pom tias kev ua haujlwm emulsification yuav tsum ncav cuag qee qhov kev xav tau ntawm kev tawg.

Lub hom phiaj ntawm kev sib xyaw cov dej theem thiab cov roj theem sib cais thiab sib npaug nrog cov theem ua ntej yog kom ntseeg tau tias cov khoom sib xws ntawm tag nrho cov emulsion tom qab emulsification thiab sib tov ntawm cov roj thiab dej ob theem. Kev sib xyaw emulsification yog, qhov teeb meem kev ua haujlwm yog 50-60 degrees, cov dej theem ntxiv rau cov roj ntsuas ntsuas, nyob rau hauv lub tshuab nplawm los yog lub twj tso kua mis stirring, yog cov dej theem siab dispersed nyob rau hauv cov roj theem, tsim latex. Tab sis hom latex kua no tsis ruaj tsis khov, nres stirring tej zaum yuav nyob rau hauv cov chaw ua si roj thiab dej sib cais tshwm sim.

Tom qab cov khoom sib xyaw emulsion raug xa tawm, cov txheej txheem txias thiab plasticizing yog nqa tawm kom txog thaum cov khoom ntim.

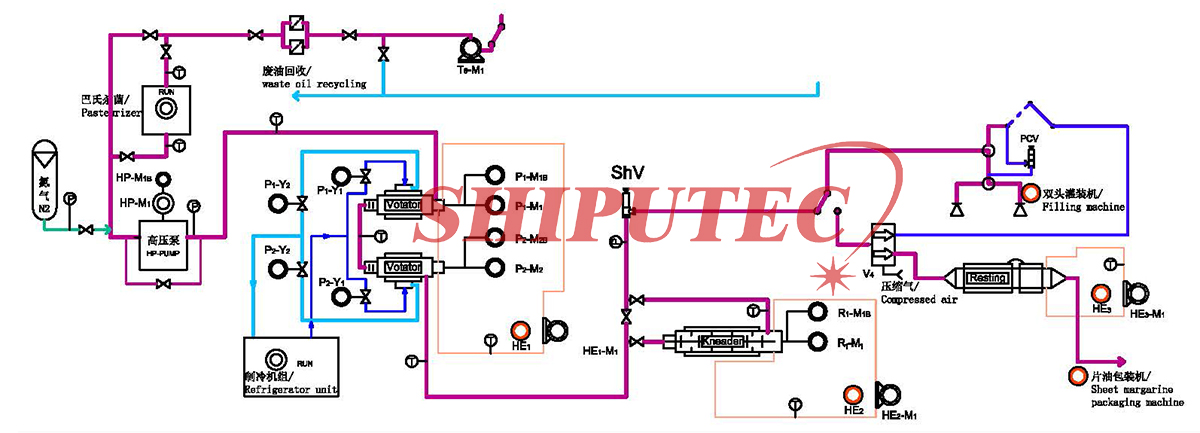

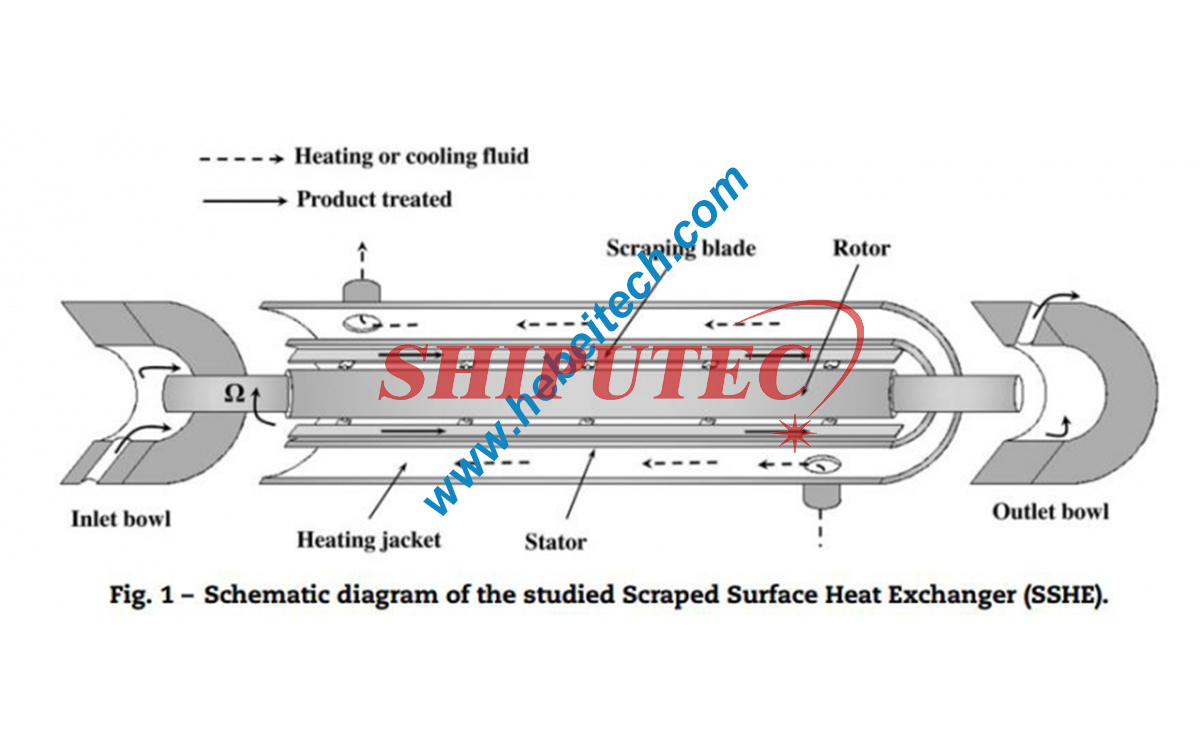

Lub emulsion yuav tsum tau txias thiab yas los tsim cov khoom lag luam margarine hloov tau. Tam sim no, nws tsuas yog siv cov khoom siv hluav taws xob kaw tas li, suav nrog cov neeg pov npav lossis hu ua scraped nto tshav kub exchanger (unit A), pin rotor tshuab lossis kneading tshuab (unit C) thiab so tube (unit B). Cov txheej txheem thev naus laus zis tau qhia hauv daim duab 2:

Cov khoom siv no muaj cov yam ntxwv hauv qab no:

1. Kev kub siab airtight ua haujlwm tas li

Lub premixed emulsion yog pub rau hauv lub tog raj kheej quench los ntawm lub twj tso kua mis siab rau cov neeg pov npav. Kev kub siab tuaj yeem kov yeej kev tawm tsam thoob plaws hauv chav tsev, ntxiv rau kev ua haujlwm siab siab tuaj yeem ua rau cov khoom nyias thiab du. Kev ua haujlwm kaw tuaj yeem tiv thaiv huab cua thiab huab cua vim quenching thiab condensation ntawm cov dej sib xyaw nrog cov emulsion, xyuas kom meej cov khoom yuav tsum tau noj qab haus huv, txo qhov poob ntawm tub yees.

2. Quenching thiab emulsification

Lub emulsion yog quenched nrog ammonia los yog Freon nyob rau hauv tus neeg xaiv tsa kom txias lub emulsion sai, thiaj li hais tias cov khoom ntawm me me crystalline hais, feem ntau 1-5 microns, thiaj li hais tias saj yog ilv. Tsis tas li ntawd, lub scraper ntawm lub rotating ncej nyob rau hauv lub votator yog sib txuas nrog lub puab phab ntsa ntawm lub tog raj kheej, yog li lub scraper nyob rau hauv lub lag luam tsis tau tsuas yog tsis tu ncua khawb lub crystallization adhering rau lub puab phab ntsa, tab sis kuj ua rau cov emulsion dispersed kom tau raws li cov kev xav tau ntawm cov khoom. emulsification xav tau ntawm lub suab.

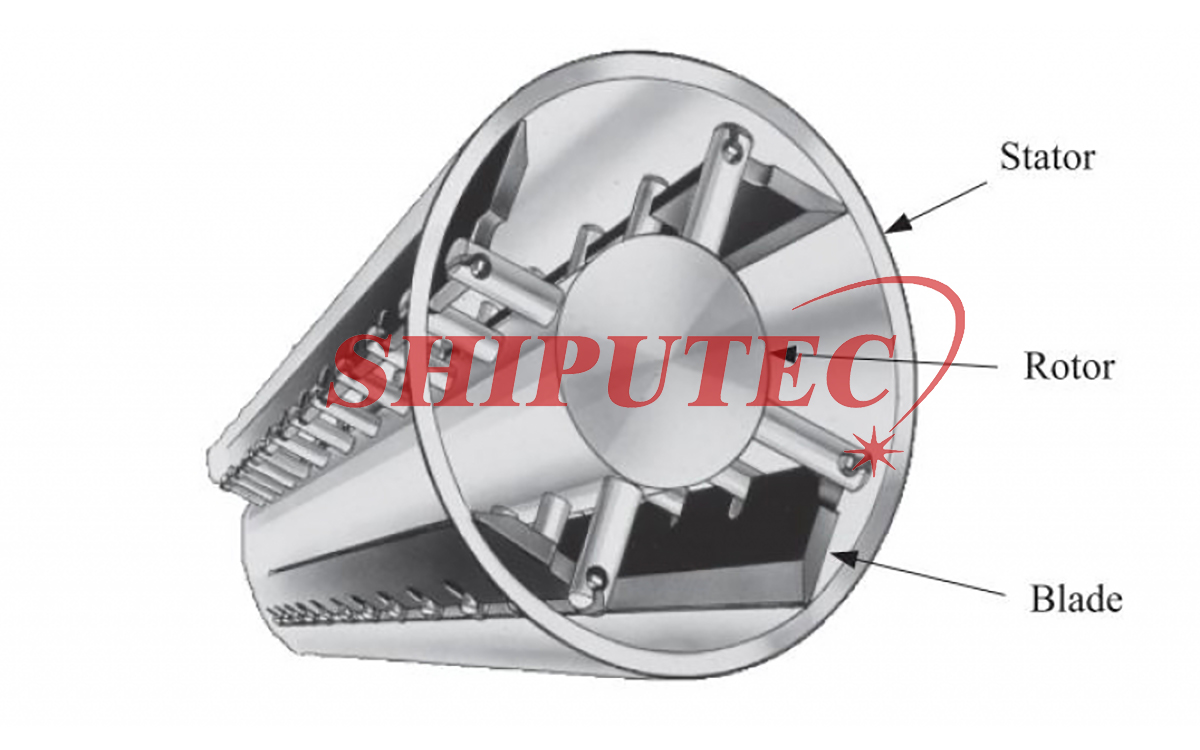

3. Kneading thiab dethickening (tus pin rotor tshuab)

Txawm hais tias cov emulsion txias los ntawm cov neeg pov npav tau pib tsim cov crystallization, nws tseem yuav tsum tau loj hlob los ntawm lub sijhawm. Yog hais tias lub emulsion raug tso cai rau crystallize ntawm so, lub network ntawm cov khoom lipid crystals yuav tsim. Qhov tshwm sim yog tias qhov txias emulsion yuav tsim ib qho nyuaj heev uas tsis muaj plasticity. Yog li ntawd, thiaj li yuav tau txais cov khoom lag luam margarine nrog qee yam plasticity, cov qauv network yuav tsum tau tawg los ntawm kev siv tshuab ua ntej cov emulsion tsim tag nrho cov qauv network, thiaj li ua tiav cov txiaj ntsig ntawm kev txo cov thickening. Kneading thiab de-thickening yog tsuas yog ua nyob rau hauv tus pin rotor tshuab.

Unit A (tus neeg pov npav) yeej yog ib qho khoom siv txias txias. Lub emulsion yog tsav mus rau hauv lub kaw tsev A (votator) los ntawm lub twj tso kua mis siab. Cov khoom siv dhau los ntawm cov channel ntawm lub tog raj kheej txias thiab lub rotating ncej, thiab cov khoom kub poob sai sai los ntawm quenching ntawm qhov nruab nrab cua txias. Ob kab ntawm scrapers yog teem rau saum npoo ntawm ncej. Cov muaju tsim nyob rau sab hauv ntawm tus neeg xaiv tsa tau muab pov tseg los ntawm kev kub ceev rotating scraper kom ib txwm nthuav tawm cov cua txias tshiab thiab tswj kom muaj cua sov zoo. Lub emulsion tuaj yeem tawg nyob rau hauv qhov kev txiav txim ntawm scraper. Thaum cov khoom dhau los ntawm chav tsev A (tus neeg pov npav), qhov kub thiab txias poob rau 10-20 degrees, uas yog qis dua qhov melting point ntawm cov roj. Txawm hais tias cov roj pib crystallize, nws tseem tsis tau tsim ib lub xeev ruaj khov. Lub sijhawm no, emulsion nyob rau hauv lub xeev ntawm txias thiab nws yog ib tug tuab kua.

Kev sib hloov axis ntawm chav tsev A (votator) yog hollow. Thaum lub sijhawm ua haujlwm, cov dej kub ntawm 50-60 degrees yog nchuav rau hauv qhov chaw ntawm kev sib hloov axis los tiv thaiv crystallization bonded thiab kho ntawm axis thiab ua rau muaj kev thaiv.

Chav tsev C (tus pin rotor tshuab) yog kneading thiab de-thickening ntaus ntawv, raws li qhia hauv daim duab saum toj no. Ob kab ntawm cov hlau bolts yog ntsia rau ntawm lub rotating ncej, thiab ib kab ntawm tsau hlau bolts yog ntsia rau ntawm lub puab phab ntsa ntawm lub tog raj kheej, uas yog staggered nrog cov hlau bolts ntawm lub ncej thiab tsis txhob kov ib leeg. Thaum cov ncej tig ntawm qhov kev kub ceev, cov hlau bolts ntawm lub ncej hla qhov sib txawv ntawm cov hlau bolts, thiab cov khoom yog kneaded tag nrho. Raws li qhov kev txiav txim no, nws tuaj yeem txhawb txoj kev loj hlob ntawm cov muaju, rhuav tshem cov qauv siv lead ua network, tsim cov crystals tsis tu ncua, txo qhov sib xws, thiab nce cov yas.

Chav tsev C (tus pin rotor tshuab) tsuas yog ua kom muaj zog kneading ntxim rau hmo ntuj txias, yog li nws tsuas yog xav tau kev txuag hluav taws xob thiab tsis xav tau txias. Raws li cov cua sov crystallization raug tso tawm (txog 50KCAL / KG), thiab cov cua sov tsim los ntawm kev sib txhuam, qhov tso tawm kub ntawm chav tsev C (pin rotor macjhine) yog siab tshaj qhov ntsuas kub. Lub sijhawm no, crystallization yog txog 70% tiav, tab sis nws tseem mos. Cov khoom kawg yog tso tawm los ntawm extrusion valve, thiab nws yuav ua nyuaj tom qab ib lub sijhawm.

Tom qab cov margarine raug xa los ntawm C chav tsev (tus pin rotor tshuab), nws yuav tsum tau kho cua sov ntawm qhov kub thiab txias. Feem ntau, cov khoom tau muab tso rau ntawm qhov kub ntawm 10 degrees hauv qab lub melting point rau ntau tshaj 48 teev. Txoj kev kho no hu ua ripening. Cov khoom siav tuaj yeem raug xa ncaj qha mus rau cov khoom noj khoom haus rau kev siv.